Facility Layout, Operation & Statistics

Water Statistics

Click on the image to enlarge, then click in the top right-hand corner to close.

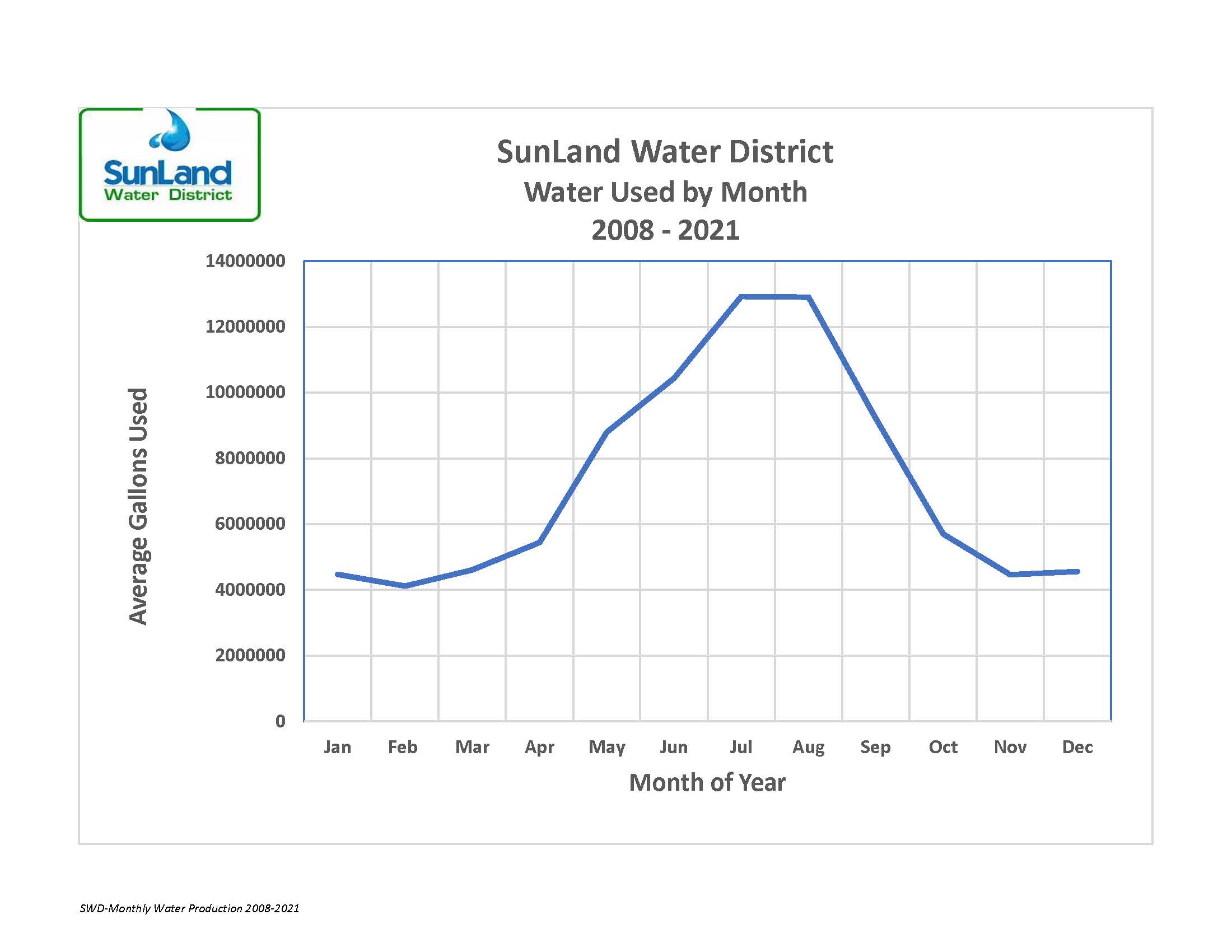

The graph shows the average number of gallons of pristine drinking water pumped to SunLand households.

Water pumped by our two wells increases dramatically during the May to September months due to irrigation and the return of our “Snowbird” neighbors. These are optimal months for practicing water conservation!

WATER RECLAMATION FACILITY – LAYOUT, OPERATION & STATISTICS

SunLand Water Reclamation Facility

Following is information about the operation of SunLand’s Sewage Treatment Plant.

Click on the image to enlarge, then click in the upper right-hand corner to close.

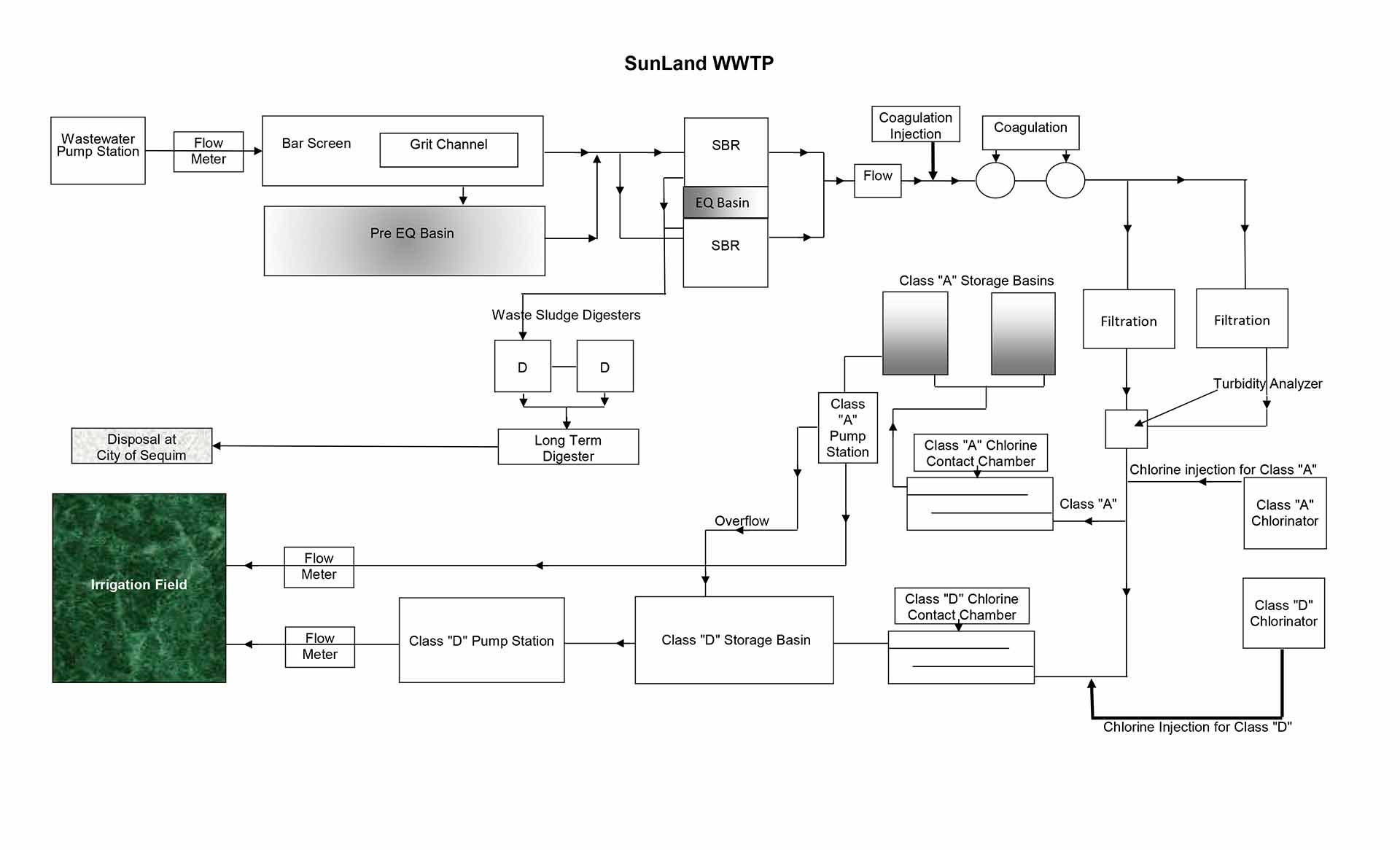

Advanced Treatment Technology;

A typical wastewater treatment facility will have aerobic oxidation and disinfection. SunLand has these plus the advanced (or tertiary) treatment of coagulation and filtration. These additional processes and a strict regimen of testing and reporting ensure our results meet mandated limits to classify SunLand as a Class “A” facility.

At many facilities, treatment to a non-polluting, environmentally safe effluent-before-discharge (usually to a surface water of some sort) is the goal. “The Class “A” water produced by the SunLand WRF is of such reliable and exceptional quality that it surpasses “adequate” and becomes a valuable resource available for several beneficial uses which potentially could include augmenting SunLand golf course irrigation in the future, helping to conserve SunLand’s excellent pure drinking water reserves.

Facility Layout

The sequence of treatment at the SunLand wastewater facility begins at the “headworks” with a bar screen and “micro-strainer” where undesirable objects in the incoming wastewater (or influent) are retained and removed mechanically, followed by a grit chamber section facilitating gravity settling of grit, sand, egg shells, etc.

Items such as dental floss, sanitary wipes, personal care products, and fine corrosives do not belong in any system and can cause expensive equipment to wear at accelerated rates. Pharmaceuticals, particularly medicines, are especially hazardous and should never be disposed of in the sink or toilet. Check with the local law enforcement regarding drug disposal locations. Another item that is hard on all facilities, but difficult to remove, is grease. Grease should go in the garbage. When these guidelines are followed, everyone benefits.

The primary effluent exiting the headworks bar screen unit then goes into our newly added 300,000- gallon pre-equalization pond which is normally ran with 60,000 gallons of wastewater. The remainder of space is for storm flows, then is batched into one of the two Sequencing Batch Reactor (SBR) tanks (or basins). An SBR has 5 specified cycles: Mix Fill, React Fill, React, Settle and Decant. The two-tank design allows alternation so that, as one basin may be settling and decanting, the other is busy mixing, filling and aerating. One basin must be available to accept influent (raw wastewater) at all times. This is necessary because, although it is pumped intermittently to the facility, a minimum of approximately 100,000 gallons of influent arrives daily.

Mix Fill

During Mix Fill, influent enters the basin and is mechanically mixed with a large volume of biomass (primarily bacteria plus protozoa and other invertebrates). “This mostly aerobic microorganism community metabolizes, oxidizes or “reduces” organic and inorganic substances for life processes and is the “core” of activated sludge process. During the Mix Fill phase, there is little or no dissolved oxygen present (anoxic), which aids in de-nitrification, phosphorous reduction and controlling filamentous bacteria (often a long, stringy bacteria that, if not controlled, and proliferate and hinger the settle process later).

React Fill

Influent continues to enter the basin and 20 horsepower air blowers cycle on and off to create alternating aerobic and anoxic conditions. Many biological and chemical reactions of importance are occurring at almost all times. Due to its prominence, Total Nitrogen Removal is probably the most important goal of all wastewater treatment facilities and is accomplished at the SunLand WRF by alternating aerobic and anoxic conditions to facilitate Nitrification/De-nitrification. Most wastewater organisms are aerobes and need dissolved oxygen to oxidize substrates to obtain energy (cellular synthesis/respiration). Nitrifying bacteria which oxidize ammonia nitrogen (NH3) to nitrite (NO2) and then to nitrates (N)3) requires oxygen. De-nitrifying bacteria convert nitrate to nitrogen gas when oxygen is not present, using the nitrate as an electron acceptor and harmlessly releasing the nitrogen gas into the air. The React Fill phase also has phosphorous uptake int o the cell mass of the organisms and biochemical oxygen demand reduction.

React

Influent stops flowing into one basin and, by timing activated valves, switches to the other basin (which begins Mix Fill). The Redact phase allows the organisms to “work on” the remaining nutrients and substrate for that particular batch. This is sometimes referred to as “polishing off”. At the end of the aerated period, the mixer stops and the aeration stops to settle the biomass.

Settle

Particles and organisms settle undisturbed to or near the bottom of the tank, leaving mostly clear treated “water: above the settled mass. (The other basin starts React Fill.)

Decant

The treated “secondary” effluent for that batch is then removed (decanted) from that basin and sent down the line for further treatment. The Decant stops at a pre-set limit in the basin so that the basin retains a mass of microorganisms in solution (74,000 gallons minimum) to treat the next batch introduced, as the entire process begins again with Mix Fill.

Waste Cycle

At the end of each Decant cycle, before starting the whole cycle again with Mix Fill, each basin has a Waste Cycle; all wastewater plans accumulate “waste sludge”, mostly consisting of solid, non-degradable constituents and excess organisms; and as the “bugs” in the working biomass continue to multiply, their numbers must be monitored and kept in “check (it is called the food-to-mass ratio of F/M); otherwise, you have a lot of full, inactive bugs that do not need to do much, as opposed to active, busy bugs that are hungry for the next batch. This approximate 1 percent “trip” each cycle is accomplished with the Waste Cycle.

The Waste Sludge goes to aerobic digesters (thanks with mechanical aerators) that continue to bio-degrade residuals, hopefully all the way to the endogenous phase (when organisms have degraded available food, then some of their own protoplasm, and finally cell lysis adds them to the mix to serve as food for other organisms).

The aerobic digesters are similar to the basins in that they cycle on and off (more on than off) with aeration, but being filled with older, mostly oxidized wastes, have much longer settle times to separate the treated water from the biomass. The treated water obtained from these settle phases is put back into the plant at the headworks to be retreated. The remainder is classified as biosolids. these biosolids are often treated to valuable, beneficial uses, mostly as fertilizer and soil amendments that increase plant yields and health. SunLand does not possess the equipment to further treat our biosolids. Therefore, the WRF trucks, by the gallon, to the City of Sequim Wastewater Treatment Plant where the biosolids can be processed further. In 2015, the WRF added a 100,000-gallon biosolids lagoon for better digestion and storage which allows the facility to decrease the amount of liquid in the sludge, thereby decreasing the amount and the cost of sludge to be processed by the City of Sequim and increasing storage space capacity at the WRF.

The Secondary Effluent that was separated from the biomass in the settle and decant phases takes a different route and is injected with a small amount of aluminum sulfate (alum) on its way to the flocculation tanks, filer, and chlorine contact chamber. The flocculation tanks provide a propeller-driven mixing environment that aids in the flocculation process. The alum helps flocculate or “gather together” small or dissolved particles remaining in the effluent so that as the effluent arrives at the disc filter (tertiary/advanced treatment), the particles will more easily catch on the cloth material. Particles are mechanically removed from the filter and returned to headworks to be retreated. Water that passes through the filter continues to disinfection.

Disinfection

All wastewater treatment plants must disinfect the effluent prior to any discharge. No matter how well a facility treats the water, disinfection is required to eliminate any pathogens (disease or illness-causing agents) that may remain. Disinfection is commonly done by exposure to ultraviolet lighting systems, chlorine gas, sodium hypochlorite solutions or ozonation. Disinfection at the SunLand SWRF is done with sodium hypochlorite. By injecting the treated effluent with sodium hypochlorite, then providing a sufficient time to mix in the chlorine contact chamber before discharge into a storage basin, disinfection is achieved.

Irrigation

The treated water is currently used to irrigate the spray field directly adjacent to the treatment plant, the grounds around the facility and as wash-down/cleaning water to spray the various tanks and equipment. Other beneficial uses may be possible in the future.

This has been a brief summary of the Water Reclamation Facility’s processes and equipment. The SWD is very proud of its facility, and the results we achieve. We are continuously trying to do an even better job.

If you would like to know more, we would be happy to show the facilities and equipment and answer any questions you may have.

Please contact:

Sunland Water District-Wastewater Treatment Plant

Phone: 360-683-3880

e-mail:wrf@sunlandwater.com